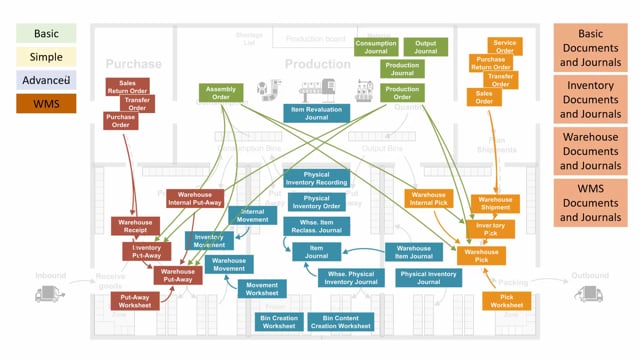

How do documents and journal work with different levels of warehouse management?

Let’s look at how we will post consumption and output from production when using different levels of warehouse management functionality. In this view, we have all the documents and all the warehouse functionality, and it’s of course very confusing so let’s dive into the different levels of warehousing.

This is what happens in the video

First of all, the basic documents, meaning if you don’t have any checkmarks on your location, you have the production order which of course requires the premium license from Microsoft.

And when you use production order, you can consume from a consumption journal or output in an output journal or you can use the production journal directly from the production order to perform both the consumption and the output.

These are the basic documents when you don’t use bins, and you don’t use any check marks on your locations.

Next level, what we call the simple level, would be if on the location card, you have checkmarks in bins or inventory picks or inventory put aways, but not in warehouse shipments or require shipments or require receive.

Normally, this will be part of using bins in the warehouse so when you start using actual bins to determine where your items are that will be the typical first level of working with simple warehouse.

From the production order, you can create an inventory pick directly and when you post the inventory pick, it would also post the consumption for the production order.

You could also make an inventory movement directly to actually move the items into the area of the production order, and then you can use the normal consumption journal to do the consumption so it’s possible to consume both from the production order and the inventory pick.

When you want to output, you create an inventory put away from the production order and from the put away, you can create a document that puts the items back into the warehouse, and when you post the inventory put away, it will also post output on the production order if you didn’t already do that.

So, it’s also possible to post output directly on the production order or through the inventory put away.

Moving on to the next level of warehouse, when you set the checkmark in require shipments on the location tab, you will have to create a warehouse pick and note in this scenario, that the warehouse pick is created directly from the production order without a sales shipment or warehouse shipment.

This means that you create the warehouse pick and when you’re done, you register the warehouse pick and after that, you will register or post consumption from the production order directly.

This means you create the warehouse pick to move the items into the production order.

You can also still consume directly on the production order.

You can also use the movement functionality to move the items into the production order and then post the consumption directly on the production order.

This could be done by the internal movement functionality to create an inventory movement, but you cannot calculate the bill of material from the production order so the internal movement will have to be created manually line by line.

Note this, when you are outputting the items from the production order, you will create an inventory put away directly from the production order and the inventory put away will post output while also moving the item into the correct bin.

So even though the inventory put away is normally intended for simple warehouse functionality using production orders, it will be also used in the advanced functionality.

The last level is the WMS level meaning the checkmark on the location called directed put away and pick and this works a little different than the advanced level.

You create a warehouse pick from the production order in the same way as from the advanced functionality and when you post the warehouse pick, it will post a movement into the production order and after posting the movement to the production order, you can post consumption through the production journal or one of the journals.

So, in this way, it’s the same functionality as the advanced location, but you could also create a warehouse internal pick to create the warehouse pick.

So, it’s also possible to manually create an internal pick if you want to move the goods into the production area.

And that could be created manually, the internal pick and from that, you can create a warehouse pick without a source document.

You can also move the items into the production area.

You have to use a movement worksheet and enter the lines manually to create a warehouse movement.

And you can require the production BOM from the production orders, we will have to enter all the lines manually in this scenario.

And finally, when you want to make output from the production order, first, you post the output in a production journal.

So, it’s actually posted and on the production bin, then from a warehouse internal put away, you can create manually the output line and create a warehouse put away.

So, to create a warehouse put away for the warehouse people to actually move the item from the production bin into the warehouse, you used the warehouse internal put away functionality.