How do you use warehouse movements to put-away finished items?

Working on a location with directed put away and pick, I will post output from a production order using a normal production journal, or an output journal. This will put the item on inventory, and it will create the warehouse entry on the production bin.

This is what happens in the video

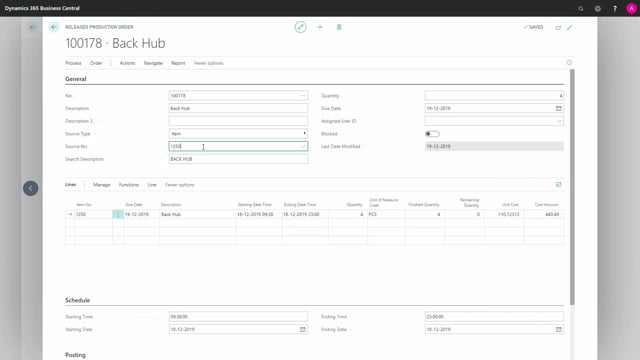

So, in this scenario, I have already posted the output and I have a warehouse entry telling me that the item is on bin 120; 4 pieces.

I could put it away back into inventory using just an inventory movement and I need to make that from a movement worksheet.

So, I will manually go to a movement worksheet, enter my item produced.

Where to pick it from, where I want to put it on inventory and in which quantity and then to just create the warehouse movement, like this, and now we have a document for the warehouse people to put away the item and now we can check it out.

It’s a warehouse movement, I can find in here, and I can just enter my warehouse movement into the bin code that I’ve made, I could have made the bin code afterwards and then post the movement to put it back on inventory.