Why use Zones in Business Central warehousing?

If you have a rather large warehouse, the point of using zones in the warehouse would be that it’s possible to distinguish between where you want to pick your items or store your pick items, your bulk items, frozen items, etc. So, using zones make it easier to have one item placed in many bins and to have default places where to pick and put away and to refill the pick bins.

This is what happens in the video

So, if you have a large and complex warehouse, the zone functionality might come in handy.

It’s set up on the location card in the field directed put away and pick.

So this is the location I’m working at.

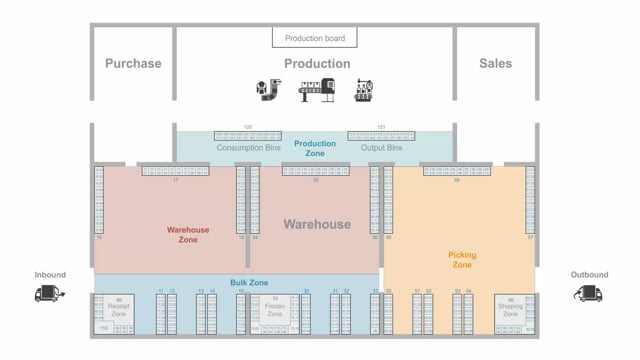

It’s my production plant in this example, and I have defined different zones in my location in this plant.

So first of all, I have a receipt zone meaning when I post a purchase receipt, it goes into my receipt zone so I can have one or several bins defined in receipt zone and I know all the items in there are still awaiting a put away.

Likewise, on the outbound side, I could have a shipping zone that contains all my bins that are marked as shipping bins or set up as shipping bins.

I would have a picking zone and I can refill my picking zone with algorithms in Business Central.

So it’s easy for me to have all my high running items in the picking zone available.

Then I could create a bulk zone for items that I want to store away and to fulfill from the bulk zone into the picking zone or the next one, which I have called my warehouse zone so this is my high running zone for picking into my production area containing my raw materials and semi-finished products.

So from the bulk zone, I will refill my warehouse zone to be able to pick faster.

Then I have a production zone.

It could have been just one bin, but I could also if I have a complex production, I could add many bins in consumption and output bins in my production zone so I could pick into that zone.

Likewise, I could have a cross docking zone in the lower-left corner and the cross docking zone is meant for items that I receive and I want to transfer it directly to the shipping zone so I don’t want to make put aways and picks.

I just want to add it directly to purchase orders.

A frozen zone or other kinds of special zone could be dedicated zones for items that need to be treated specially.

So I could add functionality on the item and on the bins on the zone that makes the item being fixed to that zone with those bins.

On my zone, I could add bins, of course, all kinds of bins and the bins will be part of the setup coming from the zone so it’s easier to control my complete inventory.