Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inHow does inbound warehouse work with bins, receipts and put-aways but not full WMS?

I will show you a flow in Business Central that looks like this, but without the directed put-away and pick checkmark in the location card, meaning with all the checkmark on the location saying warehouse receipt warehouse put-aways and bin, but not directed put-away and pick to see the difference.

This is what happens in the video

Let’s see how it looks in Business Central.

I have prepared a purchase order with two items, be aware that one of the lines has a quantity of 2 and it’s not in pieces. It’s another unit of measure code entered on the item card.

The flow will be that I release the purchase order like this afterwards, I create a warehouse receipt. And it opens the warehouse receipt.

So, I’ve opened the warehouse receipt and it has a quantity of 2 and 10, and the unit of measure code and I fill in the quantity that I want to receive like this.

And I post the warehouse receipt, which both post item ledger entries, and it posts warehouse entries into my default receipt bin, and I can see now that my quantity received is 2 and 10, and I know that it has made a warehouse put-away in here, related to this document and when I open the put-away.

I can see here that it created 4 lines with quantity 2 and quantity 10, and it’s a take line and a place line and I need to, I use this document to put the goods away on my stock and I enter the quantity to handle, and maybe I want to change the bin code if it’s different bin codes that it suggests, so I could say here this is going to another bin code like this.

And I find those bin codes while walking around the inventory and I update it afterwards in my put-away document.

Now I can register the put-away document, and this creates warehouse entries moving the items from my receipt bin to my warehouse bin. Let’s see how it looks on the item card. So if I enter my items, and I’ll just take the first one with unit of measure code on it, or a different unit of measure codes in here, and I navigate into the item ledger entries in here.

I can see that on my main location, I have received 50 which equals 2 of the unit I have received.

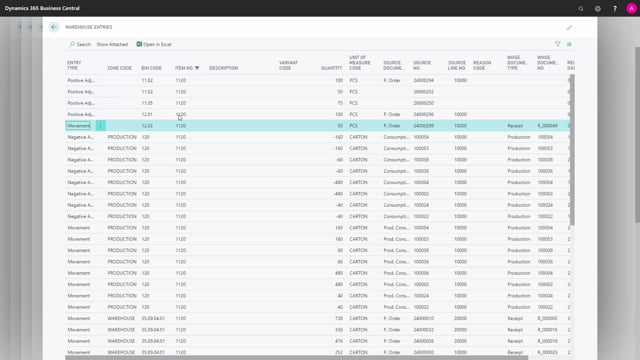

And if I look at the warehouse entries that relate to my purchase order to the line, that we just created I can see the 50 pieces. So, the warehouse entry inserts the system in base unit of measure, and not in the purchase unit of measure. This is because I don’t have the big checkmark with directed put-away and pick, meaning the warehouse entries will be split up into base unit of measure. So, if I want to use unit of measures in my warehouse entries, I need to have the big location checkmark set. You can also see this is a movement here coming from the inbound bin to the inventory bin.