What do you use the Physical Inventory Journal for?

The physical inventory journal is a journal for counting the warehouse on locations which is not directed put away, meaning not having a checkmark in the directed put away and pick.

This is what happens in the video

As an example here, if I’m entering my location that has this checkmark, I will get a validation result because it’s not possible to use the physical inventory journal for locations like that, but I can use it on all other locations, all other combination of checkmarks on the warehouse tab.

First of all, in the journal, you would normally calculate the inventory to figure out what is the actual inventory level right now according to the system.

It’s a good idea to add a posting date when you expect to post the document, meaning if you expect the inventory calculation to last for several days, make a posting date in the future.

You can calculate items that is not in inventory that will make a list of all items or you could just take the items which actually have movements.

I have filtered on two items and three locations, and normally, of course, you would not do three locations at the same time.

This is just for the example.

So normally, you would calculate one location at a time and run around and count it and then enter it in the journal.

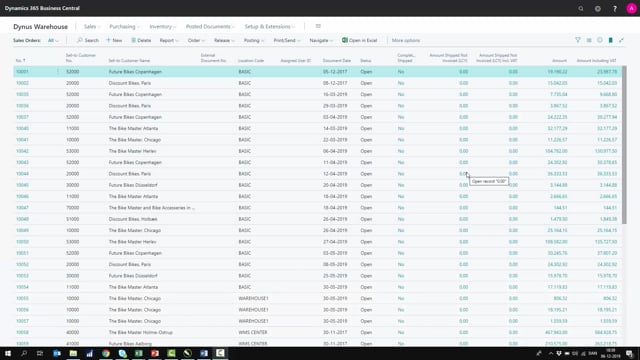

So, as you can see here, it enters or calculates the location code, the bin code on location that has bin mandatory, the calculated quantity, and a column for quantity that I can change after calculating.

Next step will be to print the report to be able to give the warehouse employee the report to use it for counting and it’s possible here to make a checkmark if you want to display the calculated quantity or not.

So, in this scenario, I will display the quantity and it is, of course, up to your strategy if you want to do that or not.

As you can see here, it displays all the lines with the location code, the bin code and the calculated quantity if you set the checkmark and there is a line where you can enter the counted quantity.

After counting in the warehouse, you will enter the actual physical counted quantity in the column quantity (physical inventory).

So, maybe we only had 272 of this one, but for some reason, six of the other one, etc.

So, when you enter a quantity in the calculated column, it will automatically make the quantity column, which is the one we actually going to post into, and it figures out if it’s a negative or a positive adjustment according to the numbers you enter in the quantity that you have calculated.

So, in this way, you can change the quantities on all the different locations on the bin.

So, for instance, like this, if I’m doing 19 and 17, it might have been an item that was misplaced.

After doing this, it’s possible to post, of course, the physical inventory journal and then it performs all of the changes.