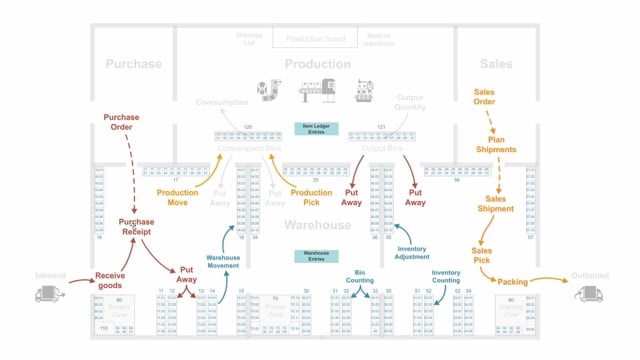

What does Warehouse Management add to the inventory processes?

With warehouse functionality, we enter bins in Business Central to distinguish between all the different places in our inventory with a unique bin code and then we can handle item per bin on the inbound and outbound side in the warehouse functionality.

This is what happens in the video

This video is just to give you a short overview of the difference from inventory and warehouse.

So in Business Central, we have inventory processes that provides item ledger entries and this is meant to handle the quantities in the system and the unit cost.

When we want to enter warehouse functionality, the first thing we do will be to enter bins in the system to distinguish between all the different places in our inventory with a unique bin code and then we can handle item per bin on the inbound and outbound side in the warehouse functionality.

When we want to enter warehouse functionality, the first thing we do will be to enter bins in the system to distinguish between all the different places in our inventory with a unique bin code and then we can handle item per bin on the inbound and outbound side in the warehouse functionality.

We can create a purchase receipt and a sales shipment meaning we can start to plan multiple orders on both inbound and outbound sites to handle items in the same go, and then we can start to actually create put aways in the warehouse. This will create what we call warehouse entries and we’ll put the items into specific bins.

So whereas the receipt and the shipment will post the item ledger entry-level, the put aways will enter the item in the warehouse entry-level.

So with this functionality, we put the item into specific bins and likewise when we pick, for instance, for production orders or sales orders or assembly orders or transfer orders, we will take the items from specific bins and actually create warehouse entries, which is basically a registration of movements in the warehouse.

And then, of course, we have internal activities in the warehouse, like warehouse movements, bin counting where we want to count a specific bin inventory adjustment for correcting the inventory and then, of course, the yearly inventory counting for larger areas in the warehouse.

This is all creating warehouse entries, and those are synchronized up into the item ledger entries once in a while.